D-18 Water Injection Facility

PROJECT INFO

CLIENT: Petronas / UZMA Group

LOCATION: Offshore Sarawak, Malaysia

TYPE: Water Injection, Production Enhancement

AWARD: August 2015

START-UP DATE: August 2016

ABOUT THE PROJECT

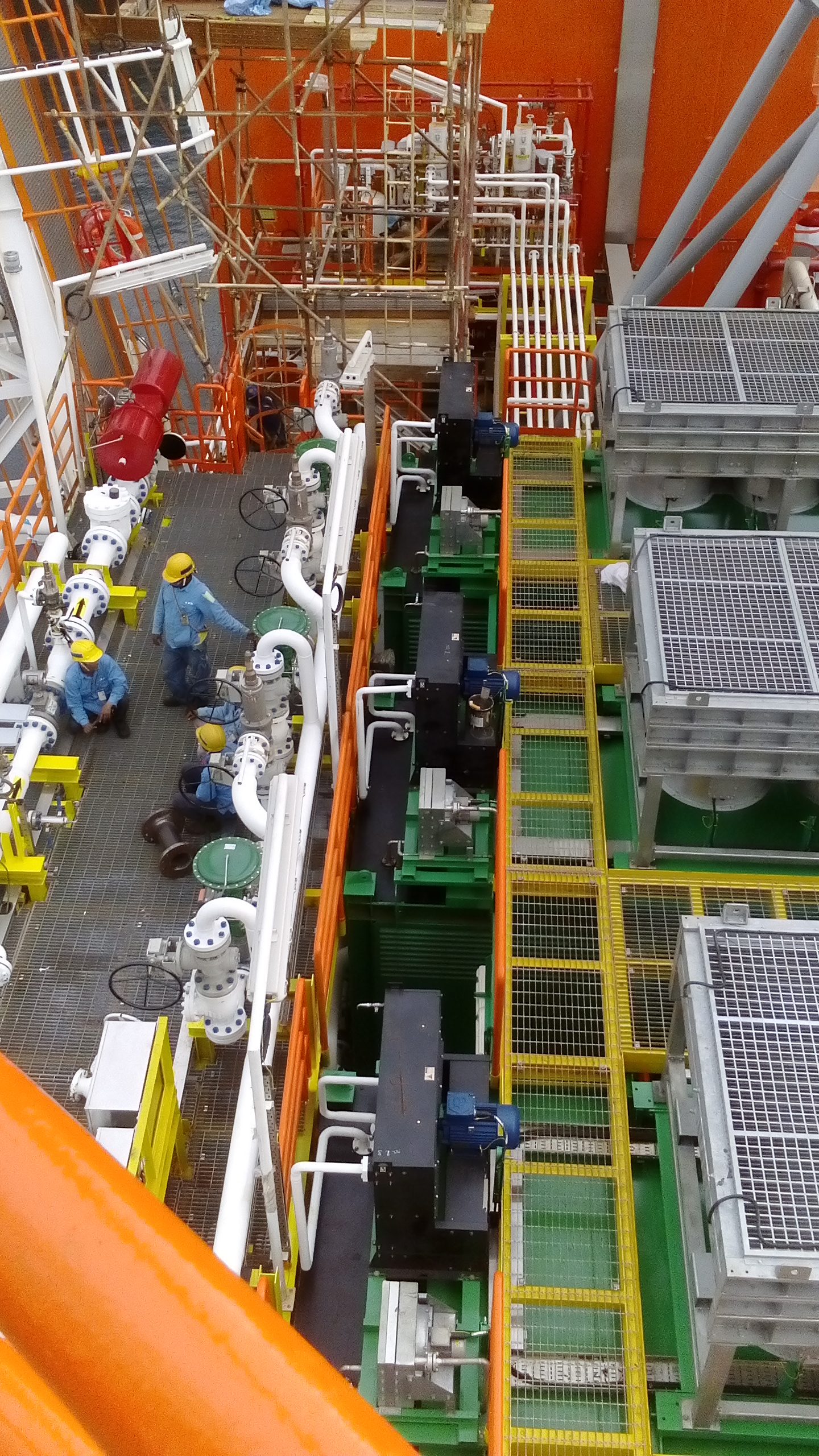

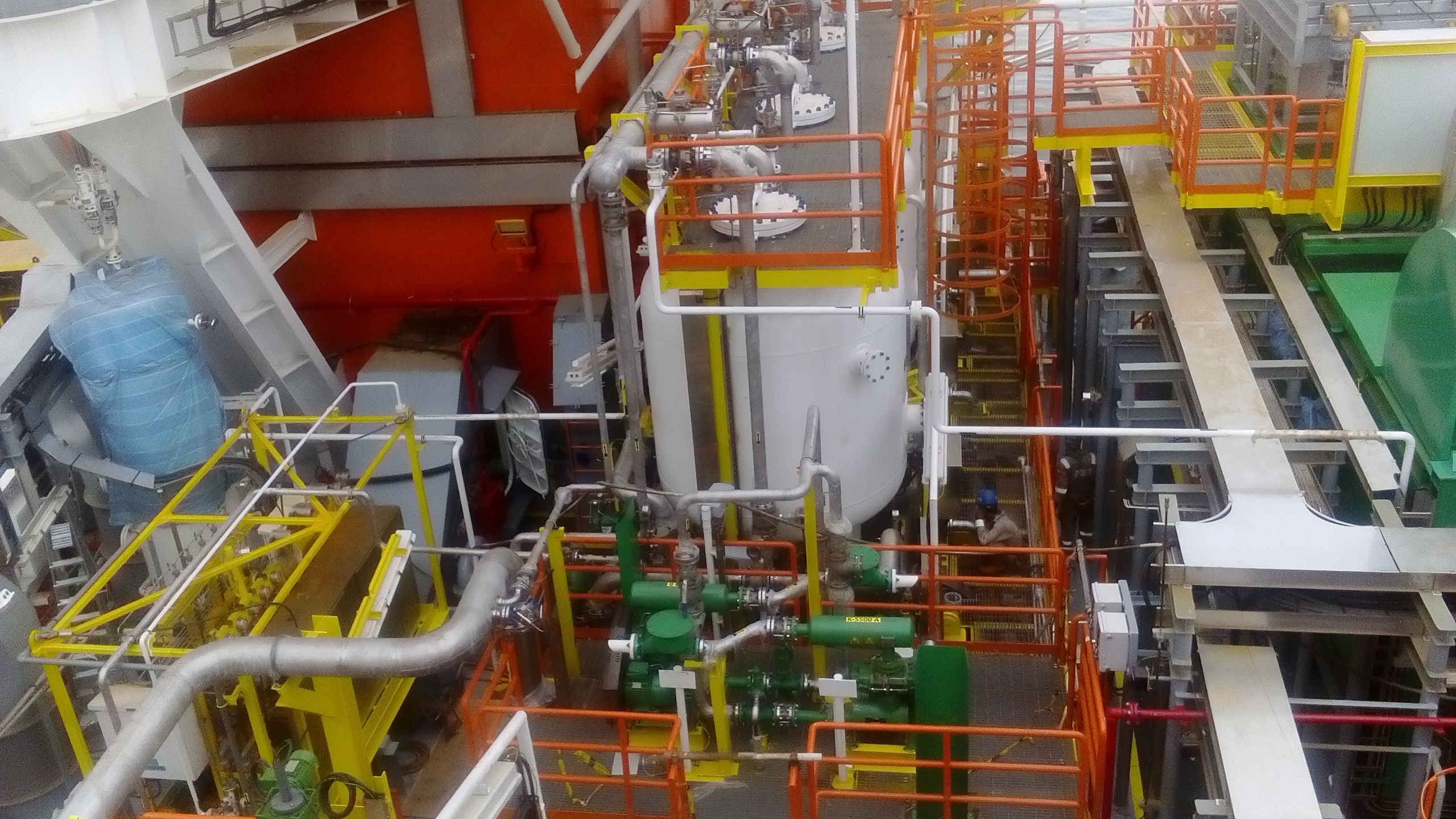

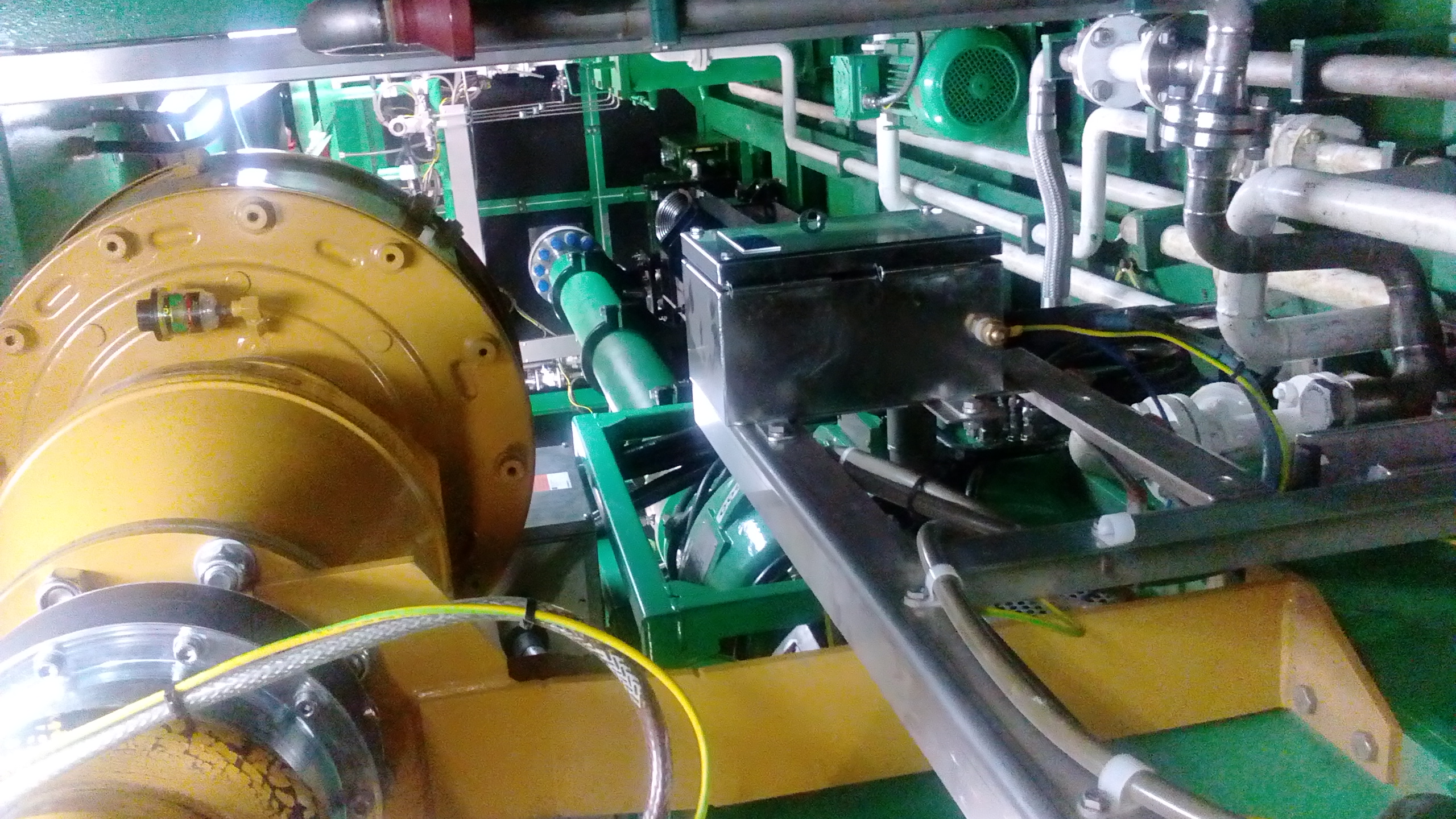

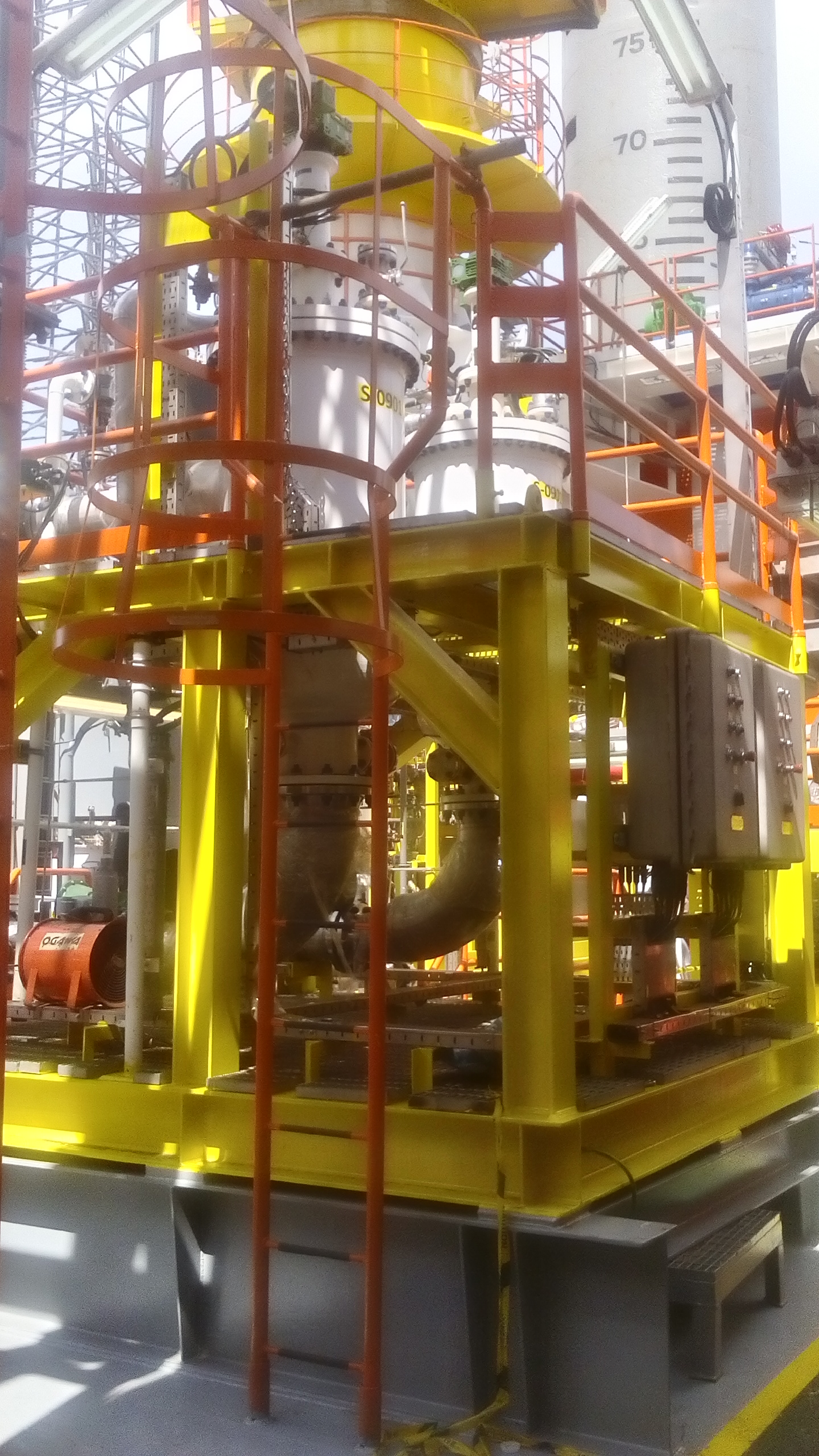

Influit were contracted by UZMA group to provide a Seawater Treatment and Injection Package for a Mobile Offshore Production Unit (MOPU). The fully automated facility lifted 66,000barrels of seawater from below the MOPU, removed 95% of particle 2microns and above via automatic backwash coarse filters and automatic bash wash fine filters. The filtrated seawater water was then deaerated via a de-aeration tower to less than 10ppb. The deoxygenated water was then injected at 1400psig in to the D-18 wells, via three Influit custom built stand alone, gas engine driven, variable speed, horizontal injection pumps. The project was designed fully to Petronas Technical Standards (PTS) which amongst other preferences resulted in the pipe work and valving being Super Duplex Stainless Steel.

Package was designed and procured by the Influit project team. The filtration packages were fabricated and assembled at the Influit fabrication facility in Batam. The Water injection pumps were fabricated in Influit’s mechanical fabrication yard in Sattahip, Thailand. Once completed the packages were shipped to the KEPPEL shipyard, Singapore for integration onto the newly renovated MOPU under the supervision of the Influit team. Influit then proceeded to carry out the final installation and commission offshore Sarawak, Malaysia.

The project was completed in 12 months from Contract award to first water.

You must be logged in to post a comment.